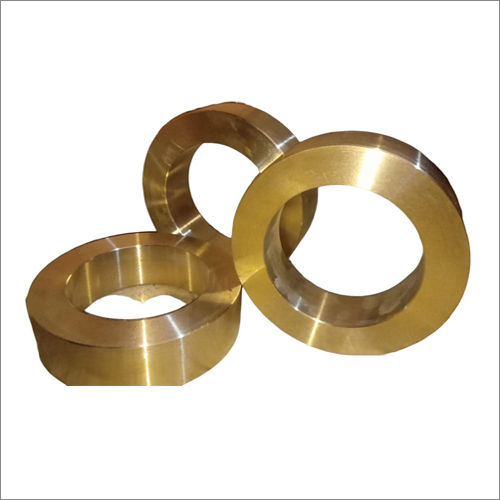

Bronze Ring

Bronze Ring Specification

- Lubrication Type

- Oil-Lubricated

- Load Capacity

- High Static and Dynamic Load Bearing

- Hardness

- 65-85 HB (Brinell Hardness)

- Temperature Range

- -40C to 250C

- Application

- Used in Engines, Compressors, Gear Assemblies

- Engine Type

- Diesel, Petrol, Industrial Engines

- Thickness

- 3 mm to 25 mm

- Surface Finish

- Precision Machined, Polished

- Shape

- Round Ring

- Tensile Strength

- 210-300 MPa

- Product Type

- Other

- Material

- Other

- Vehicle Type

- Automobile, Industrial Machinery

- Size

- Customizable, Standard Sizes Available

- Compressor Type

- Compatible with Various Compressors

- Usage

- Bearing, Sealing, Support in Rotating Parts

- Corrosion Resistance

- Excellent against Water, Oil, and Mild Acids

- Outer Diameter Range

- 30 mm to 300 mm

- Min. Order Quantity

- 100 Pieces

- Manufacturing Process

- Centrifugal Casting / Forged / Machined

- Packaging Type

- Boxed or Customized

- Inner Diameter Range

- 20 mm to 250 mm

- Friction Coefficient

- Low

- Color

- Golden Bronze

- Density

- 7.5-8.8 g/cm³

- Machinability

- Excellent

Bronze Ring Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10000 Kilograms Per Month

- Delivery Time

- 15 - 30 Days

- Main Domestic Market

- All India

About Bronze Ring

Bronze Ring is jewelry created from the versatile and tough alloy consisting primarily of copper and tin. They can be kept in the finish or polished to be glossy, or they may be left with a matte or patinated shiny for that vintage look. The bronze rings are known for their rich golden-brown color, historical significance, as well as for their vintage appeal because the use of bronze in art and ornamentation has been ongoing for thousands of years. It develops a patina over time that is beautiful and adds to its charm. Bronze Ring can be styled in various forms, including even simple bands, intricate engraved designs, and even with gemstones or any other artistic element.

Ultimate Durability and Resistance

Bronze Rings from our company are renowned for their exceptional durability. Their high-quality material composition and advanced manufacturing processes ensure excellent resistance to corrosion, even when subjected to water, oil, and mild acids. This feature extends the operational life of machinery, reducing maintenance needs and ensuring frictionless rotations.

Precision Engineering for Versatile Applications

Each bronze ring undergoes meticulous machining and polishing, offering low friction and high load capacity. The product's customizable sizing allows for seamless integration across a wide range of applications, from automobile engines to industrial machinery, compressors, and gear assemblies. Choose from standard or tailor-made sizes to suit your project's needs.

Reliable Performance in Extreme Conditions

With a working temperature range of -40C to 250C and a hardness of 65-85 HB (Brinell), these bronze rings are built to withstand varying environments and demanding workloads. Their superior static and dynamic load-bearing capabilities make them an ideal choice for high-performance requirements in diverse sectors.

FAQ's of Bronze Ring:

Q: How is the bronze ring manufactured and finished for optimal performance?

A: Our bronze rings are produced using centrifugal casting and forging processes, followed by precision machining and polishing. This sequence ensures excellent dimensional accuracy, high surface quality, and durability against wear and corrosion.Q: What types of applications can these bronze rings be used for?

A: These rings are commonly utilized in engines (both diesel and petrol), compressors, gear assemblies, industrial machinery, and as bearings, seals, or support in rotating parts. Their versatility also allows compatibility with a range of compressors and industrial engines.Q: What benefits does using a bronze ring offer over other materials?

A: Bronze rings offer high resistance to corrosion, low friction coefficient, and superior load-bearing abilities. Their machinability and precision finish also contribute to extended operational life and reduced maintenance in equipment.Q: What size and shape options are available for these bronze rings?

A: They are available in standard sizes or can be customized, with inner diameters from 20 mm to 250 mm, outer diameters ranging from 30 mm to 300 mm, and thicknesses from 3 mm to 25 mm. All rings are round-shaped, meeting diverse engineering requirements.Q: How are these bronze rings packaged and delivered?

A: Packaging typically involves boxed or customized solutions to ensure protection during transit. The minimum order quantity is 100 pieces, and products are supplied and shipped directly from India as per customer specifications.Q: When is it ideal to select this bronze ring for a project?

A: They are most suitable when projects demand high load-bearing capacity, excellent corrosion resistance, and reliable performance under varying temperatures, especially in critical mechanical or automotive assemblies.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry